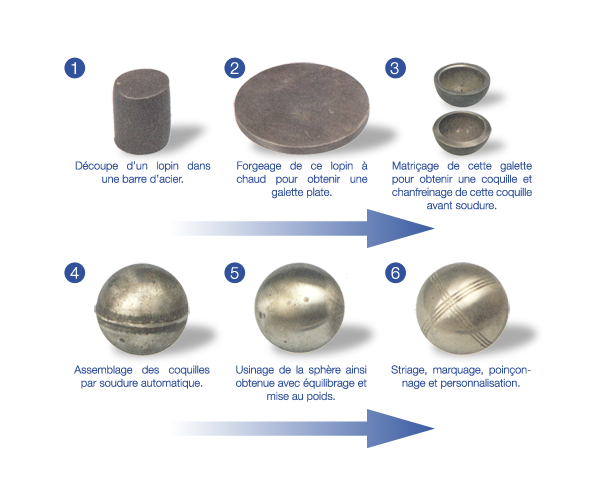

MANUFACTURING |

La Boule Bleue boules are the only ones with a 5 year guarantee (outside of normal wear and tear). |

BOULE PRÉPARATION |

|

COOKINGThe cooking phase is the “manufacturing secret” of La Boule Bleue… The boules are heated for 30 to 35 minutes in a special oven, and 850° C for carbon steel boules, and 960° C for stainless steel ones. |

|

|

|

ANNEALINGThe object of this phase is to tenderize boules of the following hardness types: semi-hard, semi-soft,tender, super-soft. The tempered boules are once again heated to a temperature of 260° C to 450° C. This second heating provides softness which will limit terrain impact rebounds, as well as the recoil when shooting an opponent’s boule. |

FINISHINGThe boules are polished to remove the calamine left by the heat treatment. Stainless steel boules are brushed, and carbon steel boules are painted to prevent oxidizing during storage. This artificial color gradually wears away upon usage. |

|

|

|

QUALITY CONTROLQuality control allows us to verify the boules’ conformity (hardness, balancing, diameter, weight). |